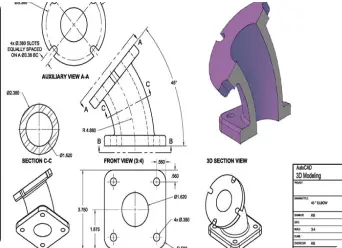

Expert engineering drawings and CAD detailing for production. CADRush create precise 2D/3D models to ensure smooth manufacturing, better quality, and faster product delivery. From detailed technical drawings to assembly views, we ensures clarity, precision, and compliance with international standards.

Our manufacturing drawing services support a broad range of engineering domains:

Component drawings for engine parts, chassis systems, and sub-assemblies.

Structural and load-bearing element detailing for industrial machinery.

Tooling and fixture design drawings for high-precision parts.

Documentation aligned with regulatory and quality system requirements

Assembly and part-level drawings for fire trucks, ambulances, and off-road vehicles.

Full-scale service to make the process industry machine line from parts, assembly, 3D/2D floor plans.

To ensure accuracy and compatibility, we utilize leading CAD platforms and adhere to recognized standards:

Well-prepared manufacturing drawings are essential for ensuring product quality, manufacturability, and cost-effective production. Key advantages include:

Manufacturing drawings deliver precise, unambiguous instructions to machinists, fabricators, and assemblers—minimizing the risk of misinterpretation during production.

They ensure alignment between the engineering design and the shop floor execution by detailing how each component should be made, finished, and assembled.

Drawings are developed in accordance with industry standards such as ASME Y14.5 and ISO GD&T conventions, ensuring compliance and interoperability across suppliers and teams.

By incorporating correct tolerances, machining features, and material specifications, manufacturing drawings reduce the likelihood of costly errors, scrap, or rework.

Well-structured drawings include part numbers, supplier references, and quality checkpoints—supporting procurement and inspection teams throughout the manufacturing process.

Individual part documentation with full dimensions, tolerances, materials, and machining notes.

Complete BOMs, exploded views, and sub-assembly structures with fastener details and annotations.

Clearly marked weld symbols, joining instructions, and fabrication notes.

Updating existing drawings to match design modifications or regulatory changes.

Delivery of comprehensive drawing sets for fabrication, inspection, and downstream workflows.

At CADRush, we view manufacturing drawings not just as deliverables, but as enablers of smooth, high-quality production. Whether you're preparing for large-scale manufacturing, developing a prototype, or updating legacy documentation, our expert team ensures that your drawings are complete, clear, and production-ready.

Let us help you translate engineering intent into manufacturing reality—accurately, efficiently, and with confidence.

A 2D Manufacturing Drawing is a detailed technical representation derived from a 3D model, containing dimensions, tolerances, materials, surface finishes, and other critical information required for fabrication and inspection.

Yes, we specialize in converting 3D models to manufacturing drawings, ensuring that every part and assembly is accurately represented for production, machining, or fabrication.

Our services include part drawings, assembly drawings, exploded views, GD&T annotations, BOM (Bill of Materials) generation, and tolerance analysis—based on industry standards and client-specific guidelines.

We deliver drawings in formats such as DWG, DXF, PDF, and native CAD formats (SLDDRW, IDW, etc.), depending on your software preference and manufacturing needs.

Yes, our drawings adhere to standards like ISO, ASME Y14.5, DIN, or customer-defined templates and layer conventions.

Yes, we can generate detailed multi-sheet drawings for large assemblies, including exploded views and part-level documentation.

Yes. We maintain version control and can revise existing 2D manufacturing drawings as per engineering changes or updated 3D models.

You can send us your 3D CAD models (STEP, IGES, SLDPRT, etc.) along with manufacturing requirements, and we’ll create precise, production-ready 2D manufacturing drawings.

Yes, we work with leading CAD tools such as SolidWorks, AutoCAD, Inventor, Creo, and Siemens NX to generate accurate and standardized manufacturing drawings.