Client: Speciality Equipment Manufacturer

Industry: Industrial Machinery Manufacturer

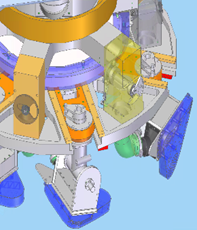

The function of a pick-and-place pad is to pick up the pad, flip it, and place it on the product conveyor. The pick-and-place pads are actuated through a customized vacuum valve, and the tilt arms are controlled by a cam profile

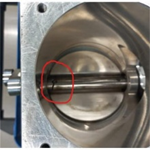

On a Friday evening, the shaft in one of the vacuum boxes of the pick-and-place pad fails, leading to shutdown of that line at the customer's premises. It was observed that the machine was operating at the peak designed load, although it normally operates at a lower speed. The client reaches out to our engineering team to perform an RCA and suggest alternatives.

Assembly Failure

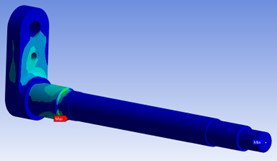

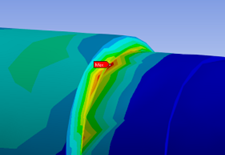

Old Shaft Stress Concentration

Strengthen the shaft by replacing the existing one with higher load-rating ball bearings, increasing the diameters and thickening the shaft cross section

Can you suggest an alternative, without changing the bearing rating?

Based on the client feedback, we did the analysis again and suggested changes to the diameter of the shaft and vacuum box bore diameter; however, this required a change in the face-width of the bearing.

Can you suggest an alternative, without changing the face width of the bearing

This option is considered as modifying the whole vacuum box and other components. Here the shaft can handle the loads and can easily operate for the period of 2 years.

This requires significant amount of modification on the vacuum box. “Suggest an alternative.”

Use an extension spring instead of a torsion spring so that standard extension springs can be used instead of custom torsion springs

“This looks interesting. Can you come up with a solution by combining elements from the previous options?”

The recommended & approved design uses the double-lobe shaft, replaces the existing torsional spring with an extension spring, and meets the design requirements. Two extension springs are attached to the spring to observe their characteristic under cyclic load. Based on Rigid Body Dynamics, the spring rating was calculated.

Conclusion – Any competent Engineer can find a solution!!

However, the difference that we offer is the planned and periodic communication on the status of the project and the willingness to work on multiple iterations and feedback until the customer is satisfied.

Write to us at support@cadrush.com if you need more information.